|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

2018

REDESIGN AND UPGRADE |

|

|

|

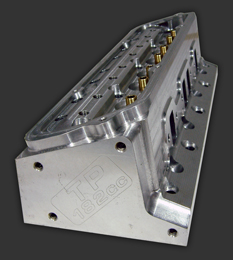

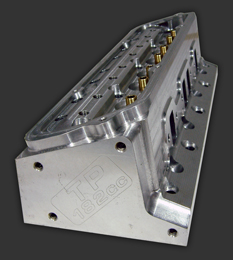

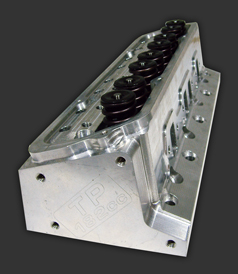

TP182cc

& TP223cc Early V8 Holden

Mid-Port

Alloy Cylinder Head

|

|

|

|

|

|

|

|

|

|

| |

Early

V8 Holden enthusiasts get ready.

The ultimate HQ-WB Mid-Port Alloy cylinder head is here.

The

latest release from Torque Power - the TP182cc/223cc Mid-Port Alloy

Cylinder Head - has been remastered with more benefits for horsepower

and reliability than any other early V8 Holden head for sale on the

market today. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

BREAK

THROUGH

With

the new TP182cc/223cc & the flow rate that is achievable as cast,

Holden enthusiasts will no longer need to purchase VN - EFi style heads

to achieve upto 600+ HP. This is a huge benefit, and not to mention,

a massive cost saving - when undertaking a VN - EFi head conversion/upgrade;

exhaust pipes, cam, lifters, pistons, rocker covers & manifold need

to all be purchased again to accommodate an VN - EFi head design.

NOT

ANY MORE. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

Spec

1 - Bare Head

'As

Cast' ports & chambers |

|

Spec

2 - Bare Head

'As

Cast' ports & CNC machined chambers |

|

Spec

3 - Fully Loaded

Fully

CNC ported or 'As Cast' with CNC chambers (also available bare) |

|

| |

|

Benefits

of the newly remastered TP182cc/223cc

-

New chamber design for better burning

-

One piece rocker rail for valve train stability

- Large 5/8" or 16mm drain back holes, which is a massive assistance

with oil return

- Thicker deck of 0.625"

- Big 9/16" (14mm) push rod holes to suit 3/8" push rods

- Bare as cast heads TP182cc are supplied with CNC chambers

- TP182cc heads can be purchased loaded as well

- TP182cc heads are available in CNC ported versions

- Heads available in 4 and 6 stud designs

- One piece water jacket

- New spark plug location

- Fully CNC machined outer-casting

One

of the most noticeable improvement in the TP182cc over other aftermarket

heads available today is the design provision to have two extra head

studs per cylinder. This will provide racers with the extra clamping

force required on the head gasket when high combustion pressures that

are obtained when turbos, superchargers and nitrous are used.

Another

key feature are that the valve angle is still 5° providing OAHF

(optimum average head flow).

The

As Cast head has 2.055 intake and 1.600" exhaust ports. The fully

CNC ported head has 2.080" intake and 1.600" exhaust ports. |

|

|

|

| |

|

|

|

|

Available

Configurations

The

TP182cc is available bare, either As Cast (ports & chambers) or

with As Cast ports and CNC machined chambers. The TP182cc cylinder head

is also available with the ultimate CNC ported package - machined chambers,

intake and exhaust ports. All configurations are available with or without

seats cut.

Heads

can also be purchased fully loaded in all above configurations, and

also in both Top End and Cam & Manifold Kits with several different

spring packages. |

|

|

|

TP182cc

& TP223cc DESIGN FEATURES |

|

|

|

|

|

|

|

|

|

|

| |

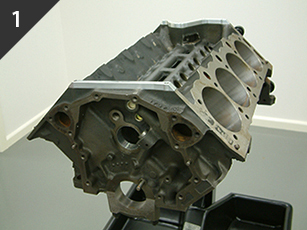

NEW

VALLEY SPACER DESIGN SUPPLIED WITH HEADS.

Due

to the higher port design of the remastered TP182cc head, standard engine

blocks require additional height to seal the manifold.

Our new heads come with our Custom Valley Spacer Set supplied. This

machined set of billet alloy ribs align perfectly to the top of the

engine block, compensating for the gap created by the cylinder heads,

enabling a precision seal of the manifold to the block (as seen in pics

1-4).

Want

to achieve a seamless result? When using the Big Paw or Little Paw block,

no valley spacer is required to align & seal the block, heads &

manifold together. |

|

EASY

STEP GUIDE FOR

VALLEY SPACER INSTALLATION |

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

ACHIEVE

MAXIMUM OUTPUT.

The

TP001 Hi-Rise Single Plane & TP020 Dual Plane Hi-Rise intake manifolds

for early Holden V8's are designed to reach maximum output of the TP182cc

cylinder head. Both heads and either manifold can be purchased together

as a Top End Package, as seen together in pics 3 & 4 to right. |

|

|

| |

|

|

| |

|

TP182cc

&TP223cc

HEAD SPECIFICATIONS

AND FLOW FIGURES

|

|

|

|

|

| |

|

|

| |

|

Machined

Specs

Intake Port

Volume

Exhaust Port

Volume

Chamber Volume

Intake Valve

Dia.

Exhaust Valve

Dia. |

As

Cast

194cc

67cc

54cc

2.055/2.080

1.600 |

Ported

223cc

79cc

54cc

2.080

1.600 |

|

|

| |

|

|

| |

|

|

|

| |

TP182cc

Mid-Port Flow Figures - As Cast with CNC Chambers

Flowed @ 28” - 2.055” intake 1.600” exhaust

valve with a 4" bore |

|

|

|

VALVE

LIFT |

100 |

200 |

300 |

400 |

500 |

550 |

600 |

650 |

700 |

750 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTAKE |

63.5 |

124.6 |

179.6 |

229.7 |

249.9 |

253.8 |

253.8 |

253.8 |

257.6 |

257.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST |

50.7 |

110.4 |

151.2 |

175.1 |

177.8 |

177.8 |

177.8 |

177.8 |

175.1 |

|

|

|

|

|

| |

TP182cc

Mid-Port Flow Figures - As Cast with CNC Chambers

Flowed @ 28” - 2.080” intake 1.600” exhaust

valve with a 4" bore |

|

|

VALVE

LIFT |

100 |

200 |

300 |

400 |

500 |

550 |

600 |

650 |

700 |

750 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTAKE |

65.8 |

131.8 |

190.1 |

233.7 |

262.3 |

270.9 |

277.5 |

281.1 |

281.2 |

281.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST |

56.7 |

109.3 |

155.8 |

178 |

181 |

181.8 |

181.8 |

182.6 |

183.3 |

183.3 |

|

|

|

|

| |

TP223cc

Mid-Port Flow Figures - Fully CNC Ported

Flowed @ 28” - 2.080” intake 1.600”

exhaust valve with a 4.030" bore |

|

|

VALVE

LIFT |

200 |

300 |

400 |

500 |

550 |

600 |

650 |

700 |

750 |

800 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTAKE |

142.3 |

200.4 |

248.5 |

289.9 |

298.5 |

307.4 |

313.8 |

315.5 |

317.9 |

317.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST |

104.8 |

148.5 |

186.6 |

217.4 |

222.9 |

226.2 |

228.2 |

230.4 |

232.0 |

232.5 |

|

|

|

|

|

For

any further information and pricing required on these new cylinder heads,

contact Craig Bennett at Torque Power on 0419 359 143 or (03) 5248 5668 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|